While these standards are for 1:32 scale wheels, they are also applicable to other scales operating on gauge 1 track (i.e. 1:225., 1:20.3, et al.). The "IF" measurements are for use with "finescale" wheels. For the larger scales, the flanges and treads come closer to representing actual scale tread sizes.

I would recommend that those turning wheel castings to a finished profile consult an article in Model Engineer magazine (Vol. 161, No 3832, p. 282) entitled "Wheel Turning". Author Barry Applegate describes a prodecure for assuring that all the diameters on the wheel are concentric after turning. (This is not as easy as it would appear before you have done it!)

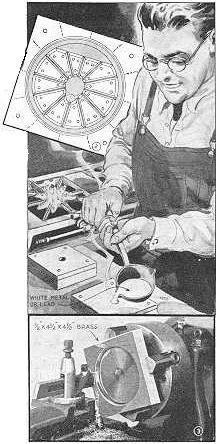

ODELMAKERS who build

locomotives

need not go to the expense of purchasing the wheels, Fig. 1, if

they

cast

them in these brass molds, which can be used repeatedly. The molds

shown

are not dimensioned to a particular scale, but by following the

instructions

you can make them to any desired scale. All you need is two small

pieces

of brass, one a little thicker than the wheels to be cast to serve

as

the

mold, and the other to serve as a cover.

ODELMAKERS who build

locomotives

need not go to the expense of purchasing the wheels, Fig. 1, if

they

cast

them in these brass molds, which can be used repeatedly. The molds

shown

are not dimensioned to a particular scale, but by following the

instructions

you can make them to any desired scale. All you need is two small

pieces

of brass, one a little thicker than the wheels to be cast to serve

as

the

mold, and the other to serve as a cover.

![]() First, chuck

the

thick

piece in a lathe and turn it to form a profile of the wheel to be

cast,

Fig. 3. Turn the depression for the hub, tire and tire flange, and

then

turn the rest of the profile to equal the thickness of the spokes.

Be

sure

to allow a 2-degree draft or taper on the hub and tire-flange

depressions.

This is necessary to assure easy removel of the casting. It may be

necessary,

after turning the hub depression, to use a mill to elongate it to

form

the crank lug.

First, chuck

the

thick

piece in a lathe and turn it to form a profile of the wheel to be

cast,

Fig. 3. Turn the depression for the hub, tire and tire flange, and

then

turn the rest of the profile to equal the thickness of the spokes.

Be

sure

to allow a 2-degree draft or taper on the hub and tire-flange

depressions.

This is necessary to assure easy removel of the casting. It may be

necessary,

after turning the hub depression, to use a mill to elongate it to

form

the crank lug.

![]() The next step

is

to cut

segments and rivet them in the mold to form the spokes, Fig. 2.

These

can

be cut from brass on a jigsaw, using a jeweler's blade. Tilt the

saw

table

at a 2-degree angle to taper the segment edges to get the

necessary

draft.

Now, cuts or scores should be made in the face of the mold from

each

spoke

position as indicated by the dotted lines in Fig. 2, to allow air

to

escape

when pouring the metal.

The next step

is

to cut

segments and rivet them in the mold to form the spokes, Fig. 2.

These

can

be cut from brass on a jigsaw, using a jeweler's blade. Tilt the

saw

table

at a 2-degree angle to taper the segment edges to get the

necessary

draft.

Now, cuts or scores should be made in the face of the mold from

each

spoke

position as indicated by the dotted lines in Fig. 2, to allow air

to

escape

when pouring the metal.

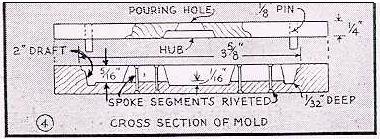

![]() The upper half of the mold is quite simple to make. It is fitted

with

four

pins to engage holes in the lower half of the mold. A tapered hole

is

bored

out on the lathe to form a hub for the inside of the wheel, and is

continued

right through the plate by drilling, Fig. 4. This hole is for

pouring

and

should be countersunk on the inside to permit easy removal from

the

casting.

Before using the mold, it should be heated slightly and smoked

well on

the inside.

The upper half of the mold is quite simple to make. It is fitted

with

four

pins to engage holes in the lower half of the mold. A tapered hole

is

bored

out on the lathe to form a hub for the inside of the wheel, and is

continued

right through the plate by drilling, Fig. 4. This hole is for

pouring

and

should be countersunk on the inside to permit easy removal from

the

casting.

Before using the mold, it should be heated slightly and smoked

well on

the inside.

Go

to

table of contents.

Go

to

table of contents.

Copyrights owned by the respective authors. Compiled by: Vance R. Bass. All rights reserved. Please use any and all information contained herein for your hobby enjoyment. If you're going to make money from it, talk to me first.

Last updated: 14 Feb. 1999.